The Sliced Gas Tank

Driving home from a job in San Antonio a truck dropped a bunch of strips of metal. It didn’t appear to be of any consequence until later.

Needing gas I filled up and headed home putting the car in the garage though with a slight scent of gas, presumably from filling it up and spilling some. Spoiler, that wasn’t why.

An inconvenience I thought, I’ll just buy another and go along my way… until I found out they’re more than $1400 for the part alone! I found some that might fit in scrap yards, but removing the tank since it’s tank and filler neck would be a serious challenge without a lift.

The goal was to try to do it without putting the car on the lift and removing it — so I tried several ideas from YouTube and other google searches for how to fix a leaking plastic gas tank.

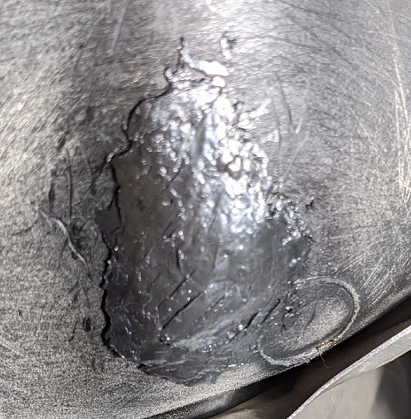

The first was to try to JBWeld it. I ran the car dry enough to where it was barely leaking, used some candle wax to stop the leaking, scuffed the area well and put a few coats of JB Weld on and it looked like this after drying for 48 hours, yes 2 days.

This repair lasted about 1 day and leaked nearly as bas as when it started. Not terribly surprising as it’s a mechanical bond on a flexing bowing vibrating piece of plastic. After a few days the whole patch fell off.

It was not time for the real guns, plastic welding. I had reservations about this due to working with a flammable liquid; however, the iron isn’t hot enough to ignite the gas (495F) and has no open flames or sparks. I used this iron from Harbor Freight, which was less than half of all the cost of my other materials costs to date (nevermind the 30 gallons of lost gas).

I again, ran the tank low, and this time I put it on the angled driveway. In this position no gas was leaking even without using wax. I cleaned the surface with brake cleaner to remove any contaminates and make for a clean adhesion.

I initially followed the instructions of only melting on new plastic and not melting any of the original plastic and it looked like this

This held great for about 3-4 days but must’ve had a hairline still exposed. You’d never know if you didn’t look under the car and see the wet plastic. It was so minor you could’ve just lived with it — and I did until the tank was low again, from normal driving.

I went over it again with more build up plastic, but the same little bit came back, so I went over the whole surface for much longer that most likely melted some of the original plastic and now 3 months later it still hasn’t leaked at all.

I should’ve done the plastic weld first. $17 and no more than half an hour of my time is all it would’ve cost.